High alumina castable is a kind of refractory castable which uses high alumina raw materials as aggregates and the powder and then be added with binding agent. High aluminum castable refractories has high mechanical strength, good thermal shock resistance, good corrosion resistance.

High alumina castable is a kind of refractory castable which uses high alumina raw materials as aggregates and the powder and then be added with binding agent. High aluminum castable refractories has high mechanical strength, good thermal shock resistance, good corrosion resistance. High temperature castable refractory is mainly used for coating, cast, furnace lining of boiler, blast furnace hot blast stove, heating furnace, ceramic kiln and various industrial furnaces.

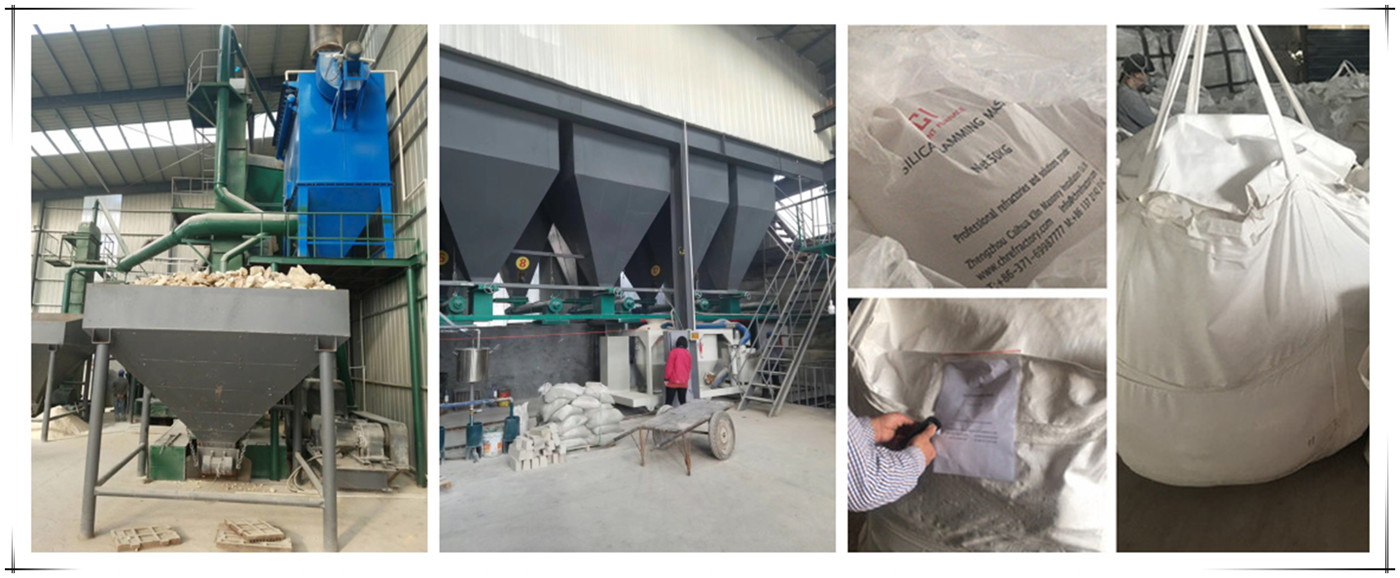

CH Refractories manufactured high alumina refractory castable materials made from high quality raw material and with reasonable distribution of particle size according to various working condition so that can make sure good performance. There are also low cement and cement free high alumina castable refractories in our factory that can meet your various requirements.

Applications of High Alumina Castable:

High alumina dense castable also called calcium clinker, is made from industrial alumina oxide powder and selected limestone powder. Refractory castable is produced after manufactured under high temperature in rotary and grind into powder. High temperature castable refractory is for making high temperature good quality refractory castables, which is a basic furnace refractory materials used in high temperature facilities in industries like metallurgy, building material, chemical, electric plant, etc.

Advantages of CH series High Alumina Castable:

• High intensity, very competitive price

•Volume stabilityement additive

•High temperature tolerance

•Good thermal shock resistance

•Good slag resistance

|

Brands |

CH-GL-85 |

CH-GL-70 |

CH-GL-60 |

CH-NT-50 |

CH-NT-42 |

|

Al2O3 , /% ≥ |

85 |

70 |

60 |

50 |

42 |

|

CaO /% ≤ |

— |

— |

— |

— |

— |

|

Refractoriness/ ℃ ≥ |

1780 |

1720 |

1700 |

1660 |

1640 |

|

Test temperature after burning is not more than ±1%(Insulation3h)/℃ |

1500 |

1450 |

1400 |

1400 |

1350 |

|

Compressive strength (after drying at 110±5°C)/Mpa ≥ |

35 |

35 |

30 |

30 |

25 |

|

Flexural strength (after drying at 110±5°C)/Mpa ≥ |

5 |

5 |

4 |

4 |

3.5 |

CH Refractories manufactures different brands ladle nozzle and collector nozzle for various capacity ladle, which can meet different service life requirements.

Corundum castable refractory is divided into cement-free corundum castable refractory and cement corundum castable refractory. Also there are different kinds of corundum castables refractory made by CH refractories company according to different raw material.

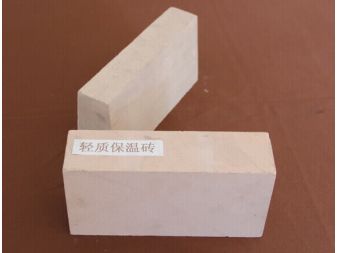

Light weight fire clay brick is made of local top grade fireclay materials under the high temperature according to the lastest national standard. The temperature in the 1200-1400 ℃. Ingredients are mixed with water made of plastic material or mud, mud with extrusion or pouring shape, 1250-1350 ℃ after dry burning oxidation atmosphere.

If you need our products please write down any questions, we will reply as soon as possible.