-

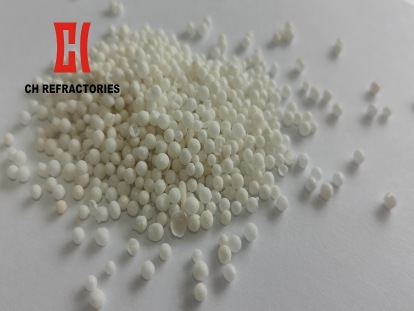

What’s refractory hollow balls?

Refractory hollow balls are important raw materials for making high-grade insulating refractory materials. Compared with ordinary insulation materials, refractory hollow sphere products have the characteristics of low density, numerous voids, few connections, high strength, high compressive load softening temperature and low re-firing linear shrinkage rate. The manufacturing methods of refractory hollow balls include electrochemical method and sintering method. The electric melting spheroidizing method involves melting refractory materials into a liquid state in an electric furnace and then blowing them out with compressed air to form hollow balls. The sintering method uses combustible materials as the core. The ball core is placed in the pelletizing disc. After adjusting the rotational speed of the pelletizing disc, the ball core is made to flip and roll inside the disc while adding a binder and dry powder of refractory raw materials. The ball core adsorbs the binder and is coated with dry powder to form a ball. Then, after drying and calcination, ceramic hollow balls are made. The hollow balls made by the powder coating forming process have the advantages of low bulk density, uniform and smooth sphere walls, high pelletizing rate, low cost, high efficiency and good performance. The commonly used hollow balls in refractory materials are made...

15-07Learn More

-

How to identify defects in the production process of refractory bricks?

The main defects in the production process of refractory bricks are underburning, overburning, damage, contamination, core encirclement, distortion, cracking, etc.

10-07Learn More

-

Classification of refractory clay

Refractory clay is the main raw material for the production of aluminosilicate refractory materials. All kinds of hard clay, soft clay, semi-soft clay and clay shale with a refractoriness requirement higher than 1580℃ are collectively referred to as refractory clay.

13-06Learn More

-

What’s the anti-skinning castable

Anti-skinning castable is made by adding silicon carbide aggregates and powder to the low-cement castable, then adding high-efficiency water reducing agent and ultrafine powder, and stirring with pure calcium aluminate cement as the binder.

28-05Learn More

-

The new definitions of refractory materials in different country

According to international standards, refractory materials are defined as non-metallic materials and products whose chemical and physical properties allow their use in high-temperature environments (excluding those containing a certain proportion of metals).

16-05Learn More

-

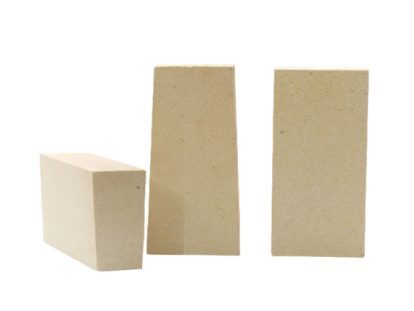

The performance between low porosity clay brick and clay brick

Clay brick is made by clay clinker and soft clay as a bond aluminum content of 30-48% stereotyped refractory. The particle composition of clay brick is generally more coarse and fine particles, and less medium particles, which ensures the strength of the brick and improves the thermal shock stability.

02-04Learn More

-

Service cycle of resistant materials for zinc smelting rotary kiln

Under normal circumstances, the calcination belt uses bricks with a body density of more than 2.9, the transition belt uses 2.6 body density of ordinary phosphate bricks or high aluminum bricks, there are also the use of magnesia-aluminum-chromium bricks, but because magnesia-aluminum-chromium bricks are expensive, the selection of manufacturers are not many, more than 95% of the use of special phosphate bricks. However, if from the use cycle, it has been a question that can not be answered precisely, because the raw materials used in zinc smelting are different, resulting in the use cycle of the lining material can not be determined.

20-03Learn More

-

The differences between Shanxi bauxite and Henan bauxite

Bauxite is playing a crucial role as an important raw material in the refractory materials industry, especially in silicon-aluminum refractory materials. In China, bauxite is mainly distributed in Shanxi, Henan, Guizhou and other places. Shanxi and Henan together account for the majority of bauxite reserves.

10-02Learn More

-

What kind of refractory castable is used for furnace lining at 1300℃

Before choosing, we must firstly consider the fuel used by the furnace, the raw material medium of the fired product, and the corrosiveness degree and nature of the raw material composition, is it acidic or alkaline? In addition, there are external factors to consider the furnace type, whether there is wind speed, mechanical stress caused by erosion wear, and then the combustion mode.

22-02Learn More

-

Light weight acid-proof castable use for chimney lining

The chimney lining is made of light weight acid-resistant castable, which has strong air tightness, and does not require light and heavy layers. The two-layer material construction reduces the thickness of the lining and improves the thermal insulation performance.

09-01Learn More

-

What kind of furnace lining is suitable to use phosphate brick?

Phosphate brick is most suitable for use in white ash kiln, zinc kiln lining, can be used for high temperature zone and transition zone. If it is a white-ash rotary kiln, the entire kiln lining can use phosphate bricks, but it is the use of high density bricks in the high temperature zone, and the use of low density bricks in the transition zone.

15-12Learn More

-

The difference between Corundum brick and chrome corundum brick

The corundum brick is a kind of refractory brick with alumina content greater than 85%, corundum brick is divided into sintered and fused corundum brick, and chrome corundum refractory brick is added to corundum Cr2O3, after high temperature molding, high temperature sintering of high-grade refractory brick, chrome corundum refractory brick is also divided into fused cast chromium, sintered chrome corundum refractory brick.

28-11Learn More