-

Characteristics and functions of refractory ramming materials

The advantage of refractory ramming material is that it can be pounded on the spot in the form of ramming, the equipment uses air pick or mechanical ramming, the amount of material is less or the use of unimportant parts, and it can also be tied by hand. However, the disadvantage of refractory ramming material is that the construction speed is faster than that of refractory castable, and the labor intensity is greater than that of castable.

09-11Learn More

-

Dry barrier refractory for electrolytic aluminum

The process of dry barrier refractory is made of clay clinker as refractory aggregate, and the third grade high aluminum clinker is processed into different granular aggregate and powder, which is processed by micro-powder technology and bonding agent.

23-10Learn More

-

The difference between high alumina brick and anti – spalling high alumina brick

High alumina brick and anti-spalling high alumina brick compared, anti-spalling high alumina brick is made of high bauxite and zircon as raw materials, high strength, chemical corrosion resistance, low thermal expansion coefficient, low thermal conductivity. And high alumina brick is made of high bauxite as raw material, chemical corrosion resistance is not as good as anti-spalling high alumina brick, mainly anti-spalling high alumina brick than high alumina brick thermal shock stability.

26-05Learn More

-

Are silicon bricks suitable for electric furnace tops?

Electric furnace top in more than 20 years ago, in foreign countries, the use of silicon brick as the top material, but in China, generally are high aluminum brick or prefabricated block to do the top. Because the top of electric arc furnace is affected by the sudden change of temperature, slag injection, gas erosion and thermal radiation, the top refractory materials must have good thermal shock stability, corrosion resistance and high refractories. Firebrick for furnace cover is an evolutionary process of silicon brick, high alumina brick, alkaline brick and amorphous refractory (large prefabricated block). Because of the poor thermal shock resistance of silicon brick, the use of furnace top only about 60 times, in China as early as 20 years ago has not used silicon brick for the top of electric furnace. Alkaline firebrick is also some of its own shortcomings, can not resist the ultra-cold, extremely hot temperature changes under ultra-high power, silicon brick and alkaline brick has been replaced by a high alumina brick, corundum brick, high alumina precast block, castable. In particular, the water-cooled furnace cover only uses refractory materials in the central part of the furnace cover. The use of molded bricks to build the...

19-05Learn More

-

Quality differences of fire clay bricks in different area in China

Fire clay bricks quality is different indifferent area in China due to the local raw materials level, for example of the clay bricks in Henan, the aluminum content is high and more purity, the body is dense, and the use effect is almost the same as the general three-level high aluminum bricks.

13-06Learn More

-

Does the castable still usable without fluidity after adding retarder?

After the castable is added with retarding agent, it cannot be used without fluidity, because the castable has difficulty condensing without fluidity, which seriously affects the strength of the castable. As for the castable manufacturers, under normal circumstances, according to the weather throughout the year, they will add coagulant in winter, and add retarder in summer to adjust the condensation of castable. Because below 5℃ and above 33℃ will affect the solidification time of castable. The most suitable temperature for the construction of castable is 15-25 ° C, if it is a fast-drying explosion-proof castable, below 15°C must be added to the binder for adjustment intervention. If the setting time is too long or the fluidity is directly lost after the addition of retarder in summer, one is that the retarder is added to excess, and the other is that the ratio of coarse particles and fine powders is unreasonable in the castable process ratio. If the ratio of coarse particles and fine powder is unreasonable, the castable will be separated and stratified when mixed with water during construction. If the fluidity of retarding agent is reduced in the laboratory, this batch of castable can not be...

12-07Learn More

-

The difference between high alumina brick and anti – spalling high alumina brick

High alumina brick and anti-spalling high alumina brick compared, anti-spalling high alumina brick is made of high bauxite and zircon as raw materials, high strength, chemical corrosion resistance, low thermal expansion coefficient, low thermal conductivity. And high alumina brick is made of high bauxite as raw material, chemical corrosion resistance is not as good as anti-spalling high alumina brick, mainly anti-spalling high alumina brick than high alumina brick thermal shock stability.

23-10Learn More

-

Does the density of light insulation brick affect the insulation effect?

Light insulation brick is divided into different materials, different body density. At present, the proportion of clay light brick will be more, if it is too high temperature insulation layer, must use suitable for different temperature insulation brick.

06-04Learn More

-

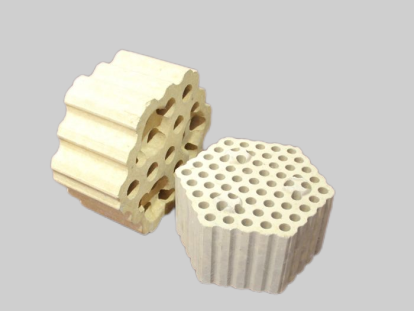

Is slotted brick necessary for lining brick for rotary kiln?

For the lining of rotary kiln, each lining ring is adjusted by slotted bricks, so there will be no brick casting in the rotation process of rotary kiln, and the service cycle is longer; If there is no slotted brick, the staggered joints in construction are not well adjusted. There will be reseam, opening, release, climbing, etc. So it is best to have slotted bricks for the lining of rotary kiln.

09-05Learn More

-

What is the role of refractory aggregate in refractory castables

What is the role of refractory aggregate in refractory castables

01-02Learn More

-

Selection of inner lining refractory materials for different rotary kilns

Selection of inner lining refractory materials for different rotary kilns

05-12Learn More

-

Refractory castable drying and baking control process

Hydration series of refractory castables, the drying process can be roughly divided into three stages. The first stage is in the temperature from room temperature to 100 degrees Celsius, generally natural drying temperature is about 40 degrees Celsius. But the fastest dehydration temperature of hydrated refractory castable is 50-60℃.

09-12Learn More