-

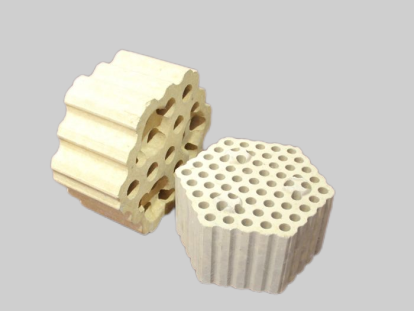

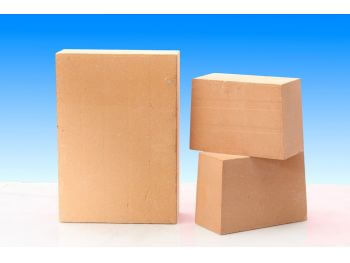

Why the price is different for high alumina bricks with same material?

The prices of high alumina bricks of the same material vary. This is mainly due to the differences in body density, shape, and quantity, which can cause significant price differences among refractory bricks of the same material.

24-07Learn More

-

The differences between high alumina composite bricks and phosphate composite bricks

Both high alumina composite bricks and phosphate composite bricks belong to composite bricks, and the lightweight parts of the composite are both designed to protect the kiln skin. However, there are differences in service temperature and wear resistance between these two types of bricks. 1. Raw Materials and Production Processes High alumina composite and phosphate composite are both formed by dividing the material zone and then high-pressure molding, but their sintering methods are different. High alumina composite bricks are sintered at high temperatures, while phosphate bricks are sintered at low temperatures. The raw materials for compounding are different: high-alumina compounding is a combination of bauxite and lightweight materials, while phosphate compounding is produced after black material and phosphoric acid solution are used as binders. Only light components are added at intervals during the molding process to optimize the compounding. 2. Performance Characteristics High alumina composites feature high-temperature resistance, high mechanical strength, and a relatively high load-softening temperature. Especially for the super-grade high alumina bricks with an aluminum content of over 80%, the load-softening temperature is even higher, and their service life is longer. Phosphate composite materials have particularly excellent wear resistance, can withstand sudden temperature changes,...

22-07Learn More

-

What refractory products is good for the water wall of the EAF settlement chamber

What refractory products is good for the water wall of the EAF settlement chamber

24-04Learn More

-

Refractories for Electric Furnace Production of Calcium carbide

Calcium carbide is an industrial name, its chemical name is calcium carbide, its molecular formula is CaC₂. What we usually call calcium carbide is actually impure calcium carbide.

17-11Learn More

-

Characteristics and uses of light insulation bricks

Light insulation brick is to point to the finalize the design of refractory brick products for porous structure inside, bulky density is small, porosity is high, sex of heat insulation high temperature is excellent, also can call light firebrick or brick of light heat preservation.

17-11Learn More

-

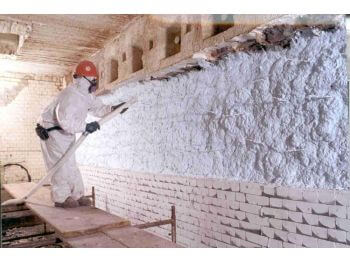

Spraying technology and application of refractory fiber

China had in 1981, the aluminum silicate fiber was the focus of the promotion, so the use of refractory fiber materials, there is a very large speed of development, because the fiber furnace lining capacity is very light, heat capacity is relatively small, so the thermal conductivity is relatively low.

17-11Learn More

-

What’s the difference between refractory mortar and refractory cement?

Refractory mortar at any time is matched with refractory bricks used materials, such bonding and masonry methods, some customers will wonder why not use refractory cement?

17-11Learn More

-

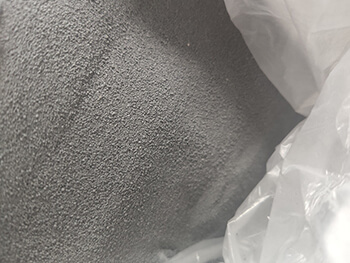

Comprehensively understand the material properties of casting powder

Casting powder is an important auxiliary material in continuous casting. Along with the development of steel-making and continuous casting technology in China, the technology of slag protection has been continuously improved.

16-11Learn More

-

What are the factors affecting the absorption of inclusions in molten steel by casting powder?

The submerged nozzle injection in the mold causes the molten steel to move convection, and the inclusions floating on the steel slag interface of the mold may be involved in the solidification shell due to the fluctuation of the liquid level of the mold, resulting in bad subcutaneous inclusions or slag inclusion on the surface and affecting the surface quality.

16-11Learn More

-

How does the casting powder lubricate in CCM?

In the process of casting, the mould vibrates up and down, and the casting billet moves downward, causing friction between the surface of the solidified shell and the copper wall, making the billet shell and the copper wall bond, increasing the resistance of the billet drawing, leading to the crack of the billet shell in the light case, and cracking of the billet shell in the serious case.

16-11Learn More

-

What are the main physical and chemical properties of continuous casting powder?

The chemical composition of each grade of protective slag should be analyzed. The content of each oxide should be within the specified range. This is the minimum index.

16-11Learn More

-

Technical characteristics of refractory castables

Refractory castable is a kind of amorphous refractory which is widely produced and used at present. Mainly used to build a variety of heating furnace lining and other integral structures. Certain quality varieties can also be used in smelting furnaces.

13-11Learn More