-

What kind of castable is used to resist erosion and slag

What kind of castable is used to resist erosion and slag

14-10Learn More

-

Effect of sodium oxide(Na2O) on properties of refractory castables

In the traditional production of refractory castable, many people pay little attention to the content of sodium oxide in alumina powder, but the content of sodium oxide in alumina has a great influence on the performance of refractory castable. The final performance of the product is for the site construction effect and use effect. Because the high content of sodium oxide will increase the amount of low melt, it will have a great influence on the dispersion of mud, and on the construction performance and setting time of refractory castable. Because the dissolution of sodium oxide into the solution will shorten the hydration time of pure aluminum calcium cement and alumina slurry, the higher the content of sodium oxide in alumina, the greater the influence of powder surface area. At the same time, the formation of hydrate, the setting time and the properties and microstructure of castable body after solidification are affected to a certain extent. The activity, integrity and surface characteristics of alumina powder will have a certain influence on the construction performance of castable, cause the construction of condensation too fast or not. The particle size distribution of alumina powder also has great influence on the...

30-05Learn More

-

Types and use of dry ramming materials

Types and use of dry ramming materials

17-06Learn More

-

How to judge the quality of refractory mortar

How to judge the quality of refractory mortar

09-05Learn More

-

The difference between silicon brick and semi-silicon brick

Silica brick is refractory product with SiO2 content above 92%. The higher the content of SiO2 in silica raw materials, the higher the refractoriness of products, the ability of acid erosion resistance is very strong. Semi-silica brick is made of pyrophyllite as the main raw material, and its refractoriness is more than 1700℃. Good thermal shock resistance, can withstand the impact of steel slag and metal, and has a strong creep resistance. Silica brick belongs to a variety of acid refractory materials, has a strong resistance to acid slag or acid melt erosion ability, alkali erosion resistance is very poor, and the expansion coefficient of silica brick is very large. The volume of silica brick is stable between 300℃ and melting point. When heated to 1450℃, volume expansion of 1.5% ~ 2.2% will occur. The biggest disadvantage of silicon brick is poor thermal shock resistance and low refractoriness (generally 1690 ~ 1730℃), so its application scope is limited. A semi-silica brick made of waxy stone. There will be micro expansibility. Because of the mineral composition of wax stone, the lattice size of pyrophyllite in its crystal structure changes little when heated, so it shrinks when roasted, and sometimes expands slightly....

15-04Learn More

-

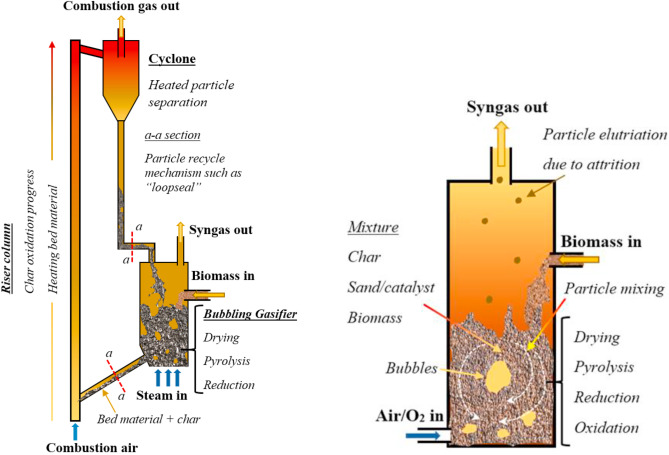

What kind of castable is used for gasifier

What kind of castable is used for gasifier

08-04Learn More

-

Advantages of Alumina Hollow Ball Brick

Advantages of Alumina Hollow Ball Brick

01-03Learn More

-

Cautions of using electrofused zirconium corundum brick(AZS Bricks)

Cautions of using electrofused zirconium corundum brick(AZS Bricks)

26-02Learn More

-

Know about Electrofused zirconium corundum brick

Know about Electrofused zirconium corundum brick

17-01Learn More

-

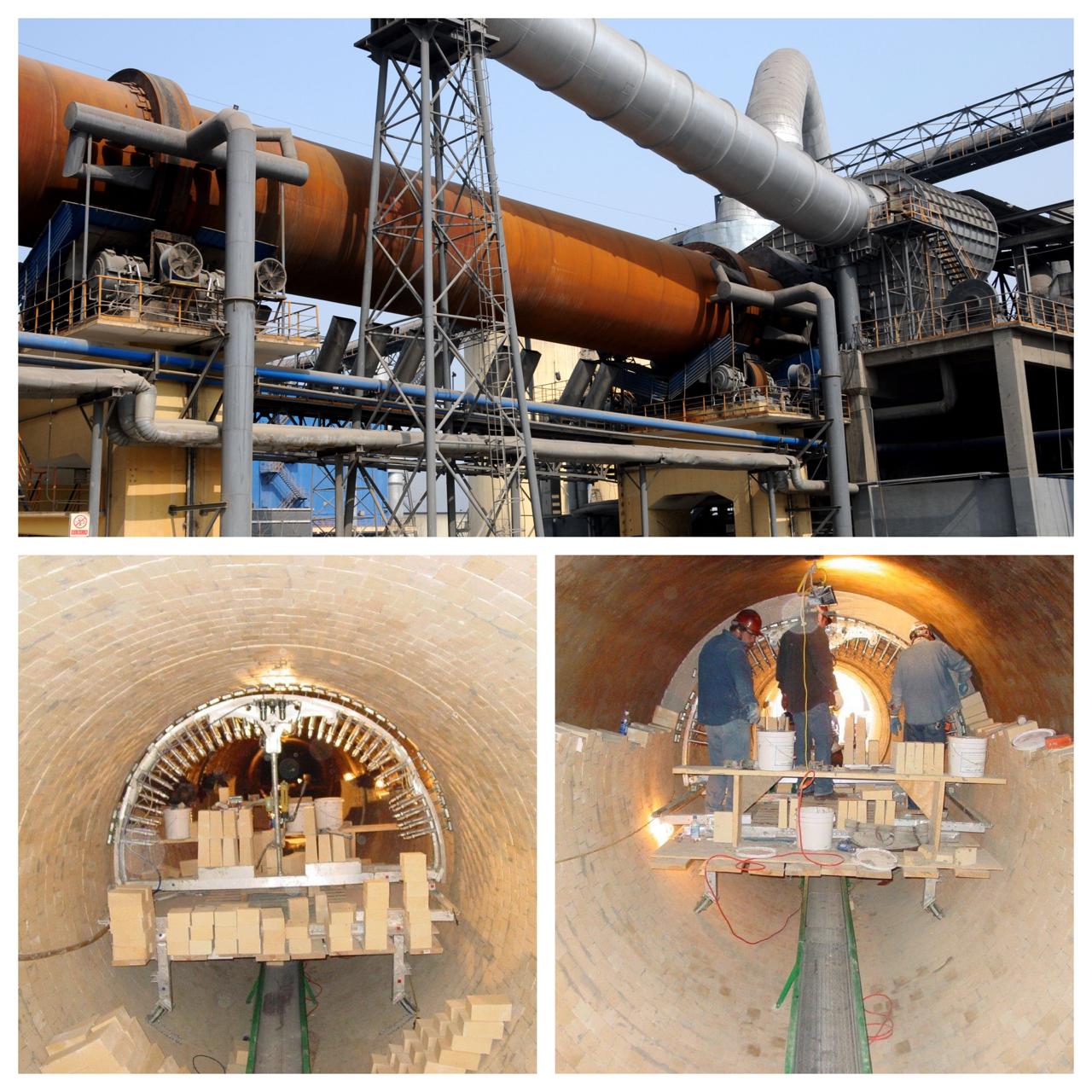

Selection of refractory materials for cement rotary kiln lining

At the back of the cement rotary kiln, the length of the kiln mouth is about 1 meter, wear-resistant castable can be selected, but it must have a certain degree of alkaline resistance. The castable area from 10D to the rear kiln entrance can use anti-spalling high-alumina bricks; The 7D-10D section of the rotary kiln can use silmo brick or Silmo red brick; Section 5D-7D is a transitional zone, which can use magnesia-aluminum spinel brick; The 6D-7D section can also use Silmo brick or Silmo red brick;

19-12Learn More

-

What factors affect the quality of low-cement castables?

The production process of this series of castables is quite strict, and there are many factors that affect the performance of low-cement castable, such as ultrafine powder, alumina cement and some other admixtures. In addition, the amount of water added, construction, and grilling are all factors that affect the quality of the castable.

01-09Learn More

-

What causes the shrinkage of refractory castables at low temperatures?

In conclusion, as the seasons change, as a manufacturer of castable materials, it is necessary to make appropriate adjustments to the binder and not remain unchanged. It should be determined based on the actual situation to meet the requirements of use and construction.

04-08Learn More