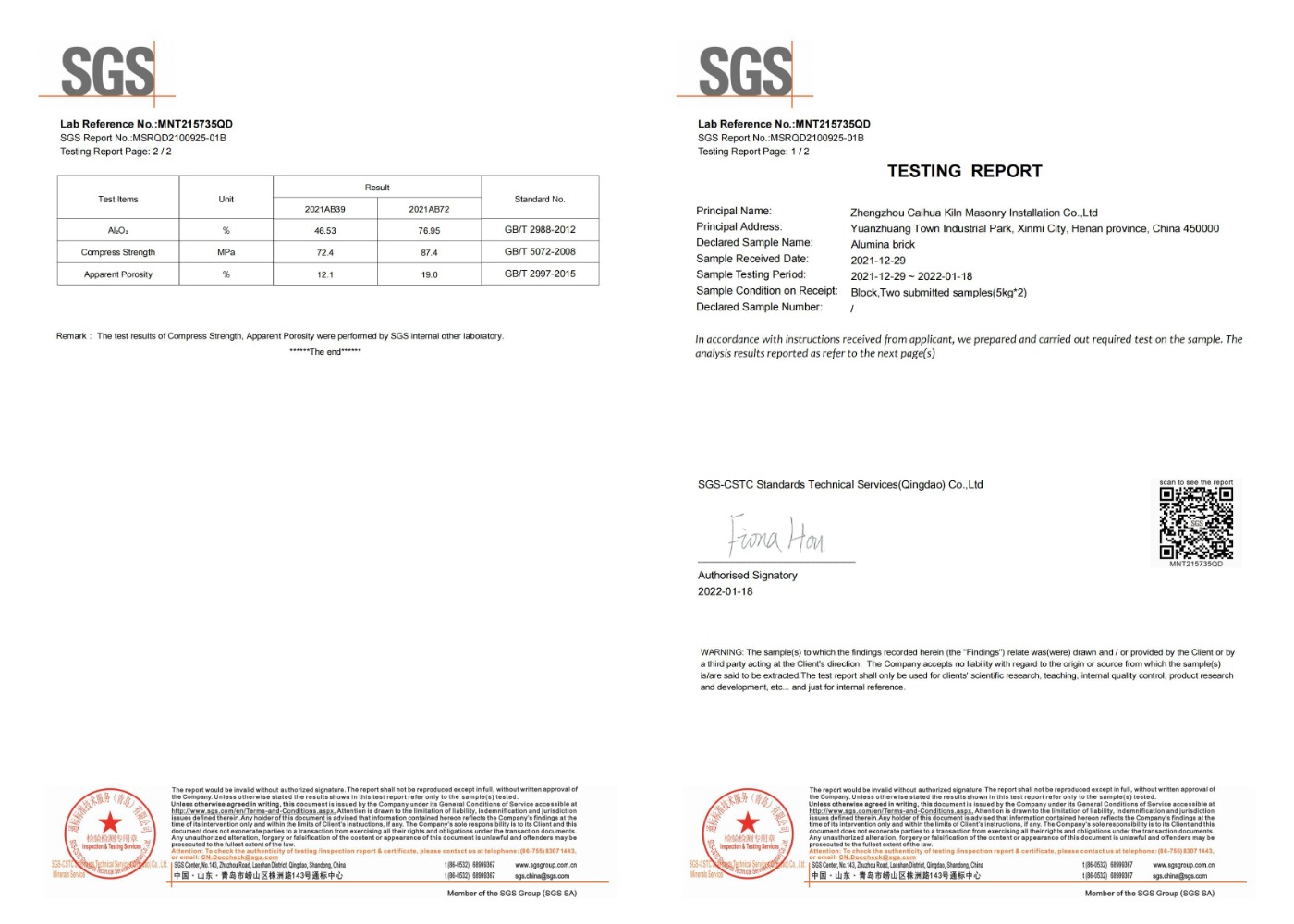

This series of high temperature kiln refractory high alumina bricks use special grade aluminum bauxite clinker as the main raw material, supplemented by special additives, high pressure forming and high temperature firing. Refractory bricks alumina has the characteristics of large heat storage capacity and small creep rate.

This series of high temperature kiln refractory high alumina bricks use special grade aluminum bauxite clinker as the main raw material, supplemented by special additives, high pressure forming and high temperature firing. Refractory bricks alumina has the characteristics of large heat storage capacity and small creep rate.

The high alumina brick made by CH refractories with very widely application and various size with free mold charge to meet different kiln applications. To be professional high alumina furnace brick manufacturer since 1984, CH refractories provides alumina lining bricks not only can design fire furnace bricks size according to your kiln or furnace drawing for free, but also suggest you the most economical refractory furnace alumina bricks price for your kiln or furnace. Generally , there are three levels lime kiln refractory high alumina brick in our plant, just please inform bricks working condition, CH refractories will suggest you the most suitable alumina refractory bricks to save your money and achieve the best performance.

Applications of High Alumina Brick:

High alumina brick is widely used in the following refractory products:

●Coke oven

●Reheating furnace

●Steel smelting furnace

●Hot Blast Stove and boiler

●Blast furnaces and carbon furnace

●Cement kiln, glass kiln and tunnel kiln

●Steel ladle lining and various kiln lining

Advantages of CH series High Alumina Brick:

●low creep rate

●Large heat storage capacity

●Customerize mould according to different size requirements for free

●high strength,good thermal shock resistance,anti-stripping,Free sample,Free construction guidance ,free 3D design

|

Items |

Index |

|||

|

/ |

CH-LZ75 |

CH-LZ65 |

CH-LZ55 |

CH-LZ48 |

|

Al2O3%≥ |

75 |

65 |

55 |

48+ |

|

CCS/Mpa ≥ |

54 |

49 |

44 |

40 |

|

Apparent porosity/% ≤ |

23 |

23 |

22 |

22 |

|

Refractoriness under load /℃ ≥ |

1520 |

1500 |

1470 |

1420 |

|

Reheating linear change(1500℃,2h) |

+0.1 -0.4 |

+0.1 -0.4 |

+0.1 -0.4 |

+0.1 -0.4(1450℃.2h) |

|

Refractoriness/℃≥ |

1790 |

1790 |

1770 |

1750 |

Kiln refractory clay brick is made from clinker clay by mixing, forming, drying, sintering and machine pressing moulding with good resistance to corrosion and abrasion, good thermal shock resistance, good spelling resistance, high mechanical strength, good volume stability under high temperature.

The tap hole clay is used to block the taphole plays an irreplaceable role in ensuring stable and high production of the blast furnace, improving the working strength and environment before the furnace, and prolonging the service life of the blast furnace.

The high-strength wear-resistant self-flowing castables are made of high-quality bauxite clinker, mullite and fused corundum. The pure calcium aluminate cement, corundum micro-powder and silicon micro-powder are used as binders.

If you need our products please write down any questions, we will reply as soon as possible.