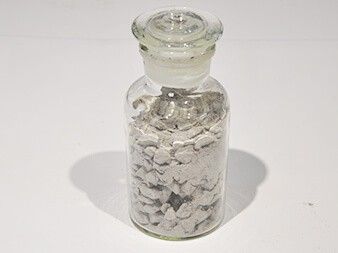

Electro-fused AZS hot refractroy repair material uses fused cast corundum refractory as raw material, adding α-alumina micro-powder to the furnish, adopting new generation ceramic binder, adding special component ultrafine powder and introducing dispersing medium, modified adding phase and chemical adding phase.

Electro-fused AZS hot refractroy repair material uses fused cast corundum refractory as raw material, adding α-alumina micro-powder to the furnish, adopting new generation ceramic binder, adding special component ultrafine powder and introducing dispersing medium, modified adding phase and chemical adding phase. High-tech composite refractory with dynamic characteristics made by special processing.

Advantage of Electro-fused AZS Hot Repair Material:

Compact structure, low porosity, high temperature resistance, erosion resistance, thermal shock resistance, high temperature volume stability, strong bonding ability and convenient construction.

Applications of Electro-fused AZS Hot Repair Material:

●As a buffer transition layer in glass kiln

●Heat repair of fused zirconia corundum bricks in glass melting furnace and aluminum masonry structures

|

Chemical composition % |

Al2O3 % ≥ |

46 |

|

|

ZrO % ≥ |

28 |

|

SiO2 % ≤ |

20 |

|

|

0.2MPa refractoriess under load/ ℃ |

1610 |

|

|

Refractoriness ℃ ≥ |

1790 |

|

|

Compressive strength/ MPa≥

|

110℃×24h Drying |

30 |

|

1450℃×3h After burning |

35 |

|

|

Use density kg/m3 |

3200 |

|

EAF tap-hole filler is developed with magnesite, forsterite and silica as the main materials according to different requirements, and shows the features of easy installation, good sintering, floating resistance, high self-open rate and good safety performance.

Base on high quality magnesite and graphite as main raw materials, low carbon MgO-C bricks are produced via pressing and low temperature pre-baking and mainly used in slag zone of ladle lined with low carbon or carbon-free refractories for low and ultra-low steel production.

Fast Drying Castable for Iron Notch is made of corundum, high quality bauxite and silicon carbide incorporated with appropriate drying agent. By firing 2 to 3 hours, the products can be put into use, and show excellent performance.

If you need our products please write down any questions, we will reply as soon as possible.