Colored Smelting

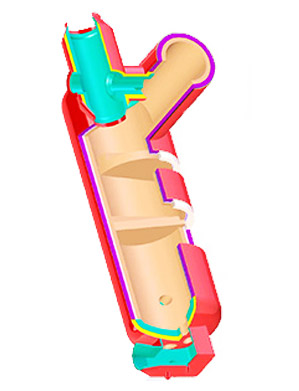

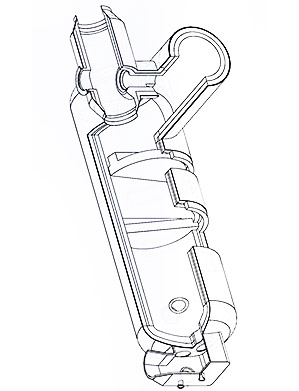

Low-nitrogen combustion sleeve burners—In terms of energy saving and environmental protection, industrial furnaces require combustion equipment to achieve high-efficiency and controllable complete combustion under different fuels and different gas gases. It is also required to effectively reduce nitrogen in the combustion process. The amount of oxide (NOx) produced ultimately achieves the goal of high efficiency, energy saving, and environmental protection.

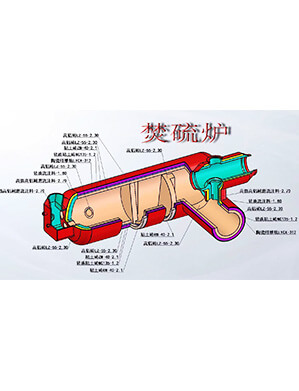

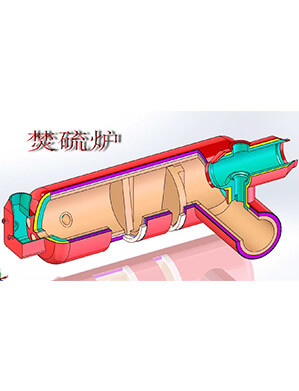

Sulphur Burning Furnace

Sulphur Burning Furnace

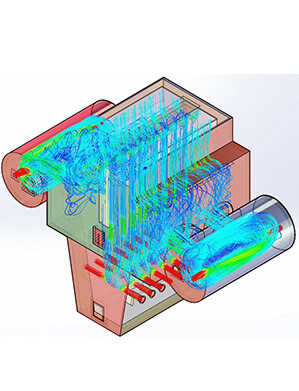

Fluid Analysis

3D Model

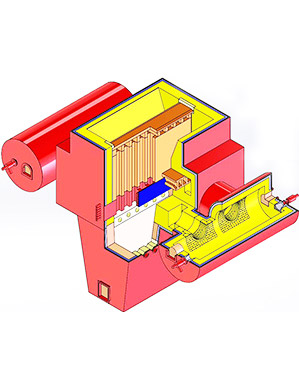

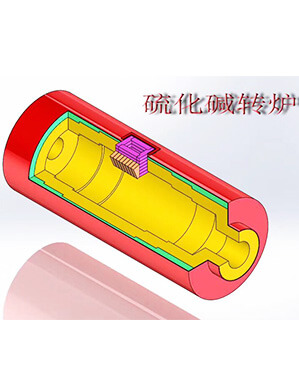

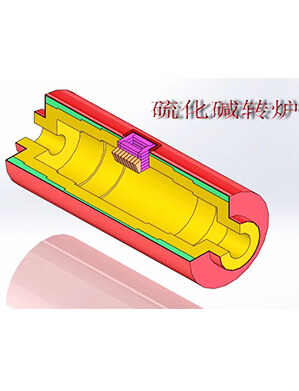

Alkali Sulfide Converter

Alkali Sulfide Converter

Sulphur Burning Furnace

Sulphur Burning Furnace

Case Implementation Process

-

01

Problem Analysis

User communication is accurate. Problems occur in the high temperature kiln

-

02

Pre-Processing

Solutions for the problem

-

03

3D Modeling Analysis

Improvement and continuous rectification to find the best solution

-

04

Iteration Calculation

Communicate with customers to show the design effect , as well as problem solving and determining the material.

-

05

Post-Processing

Result analysis

-

06

Production

Arrange production according to the drawings

By adopting such a low-nitrogen combustion combustion device on an industrial furnace, it is possible to properly control the combustion temperature and effectively reduce the emission of nitrogen oxides under the premise of achieving safe and stable combustion, thereby reducing fuel consumption and saving investment. Pollution to the atmospheric environment.