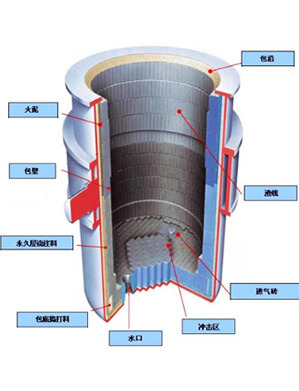

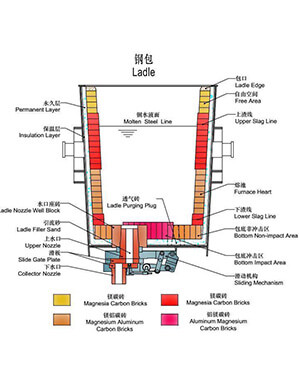

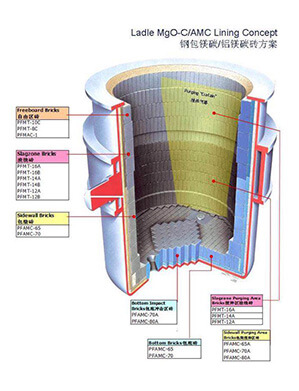

Ladle

Through the establishment of model analysis, it will positively reduce the cost of ladle refractory and reduce the difficulty of masonry operation, accurately grasp the simulation of refractory materials in various parts of ladle, and formulate reasonable ladle refractory materials according to the trial operation of the model. Specific distribution and detailed material improvement programs.

Master Plan

Site Problems

Site Problems

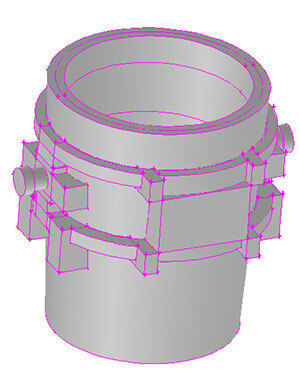

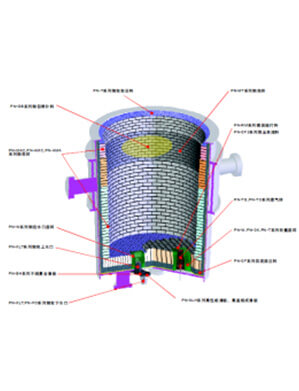

3D Modeling

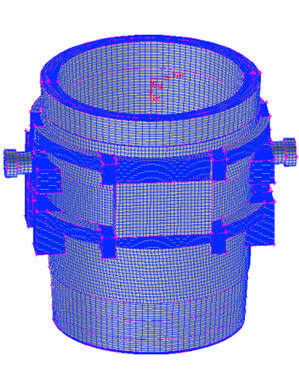

Grid Generation

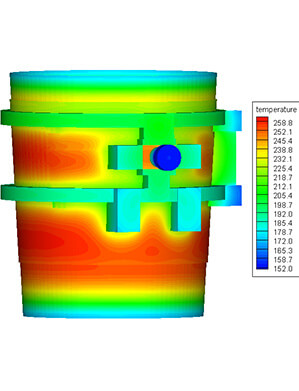

Overall Temperature Distribution

7RTD

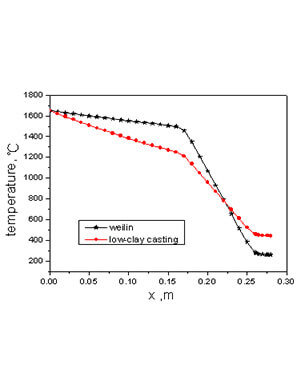

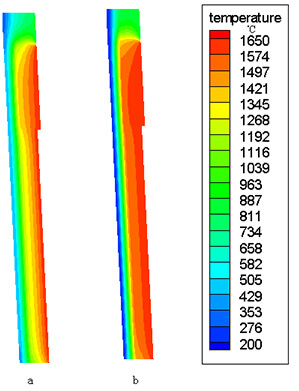

Temperature Distribution

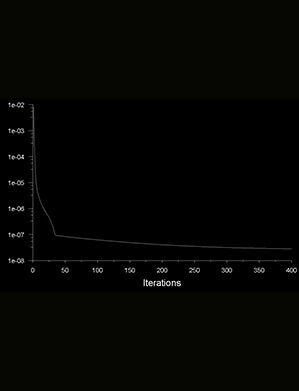

Iterative Computation

Scheme

Scheme

Scheme

Case Implementation Process

-

01

Problem Analysis

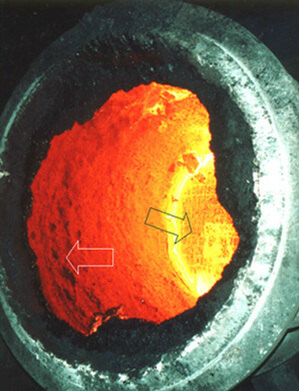

User communication is accurate. Problems occur in the high temperature kiln

-

02

Pre-Processing

Solutions for the problem

-

03

3D Modeling Analysis

Improvement and continuous rectification to find the best solution

-

04

Iteration Calculation

Communicate with customers to show the design effect , as well as problem solving and determining the material.

-

05

Post-Processing

Result analysis

-

06

Production

Arrange production according to the drawings

The application and secondary development of design software greatly improve the efficiency of actual drawing, and effectively improve the accuracy of design drawing. With the extensive application of solid modeling system and simulation analysis system of Solidworks 3D software, design drawing tape for complex equipment. Convenience has also improved the accuracy, credibility and intuitiveness of graphics, and the degree of theoretical analysis and engineering applications has been greatly enhanced.