Hot Stove Technology

The hot blast stove is a general name for the series of hot blast stoves with excellent structural stability and stability developed on the basis of Kalukin two generations of hot blast stoves. Its shape and structure characteristics mainly inherit two major structural forms of hot blast stoves, one of which is set under the spherical vault. a large-arc hot blast stove for an annular burner or a sleeve burner, and a small-arc hot blast stove with a bell-shaped pre-combustion chamber on a conical dome; the hot blast stove burner is mainly premixed and burned at a rapid rate. Premixed combustion with oxygen-enriched combustion-supported staged combustion, low-oxygen grading and low-nitrogen combustion, and partially controllable thermal storage (checker brick or refractory ball) is the main feature.

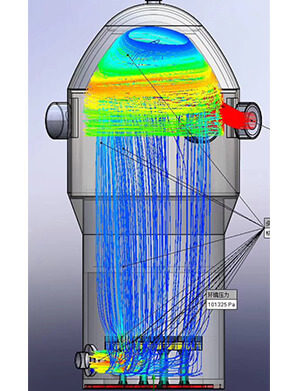

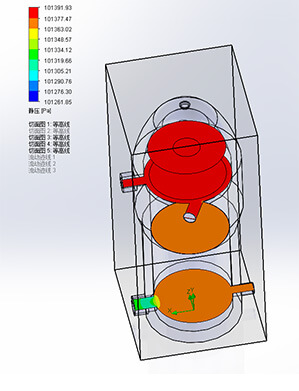

3Dflow Simulation

Section Diagram

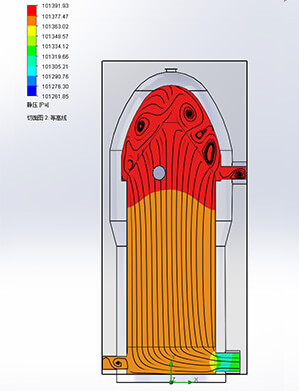

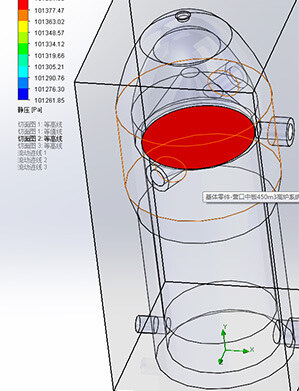

Flow Simulation

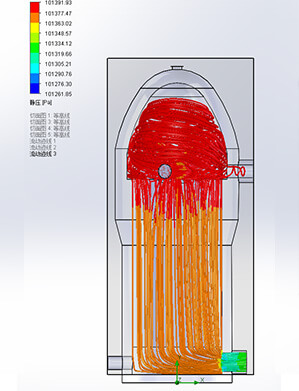

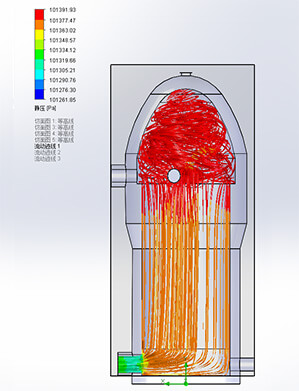

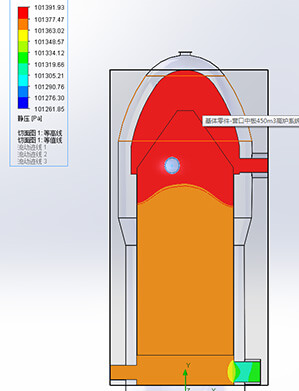

Section Map

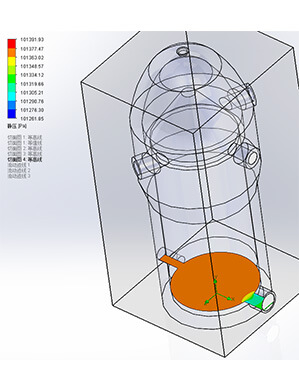

Section of Each Part

Flow Path

Contour

Section Map

Case Implementation Process

-

01

Problem Analysis

User communication is accurate. Problems occur in the high temperature kiln

-

02

Pre-Processing

Solutions for the problem

-

03

3D Modeling Analysis

Improvement and continuous rectification to find the best solution

-

04

Iteration Calculation

Communicate with customers to show the design effect , as well as problem solving and determining the material.

-

05

Post-Processing

Result analysis

-

06

Production

Arrange production according to the drawings

Such a hot blast stove can effectively realize rapid and uniform mixing of the hot blast stove combustion device and high-intensity reflux preheating combustion, effectively improving the combustion intensity and combustion stability, and effectively ensuring the high heat efficiency, high heat strength and high air supply of the hot blast stove. Operation under temperature conditions, in turn, achieves good results in saving fuel, saving investment, reducing exhaust gas temperature and harmful gas emissions, and reducing environmental pollution.