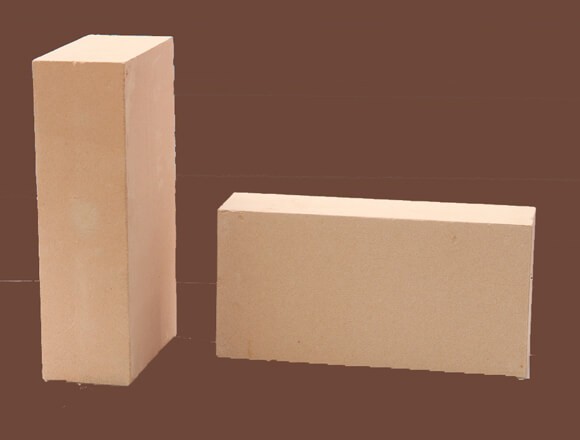

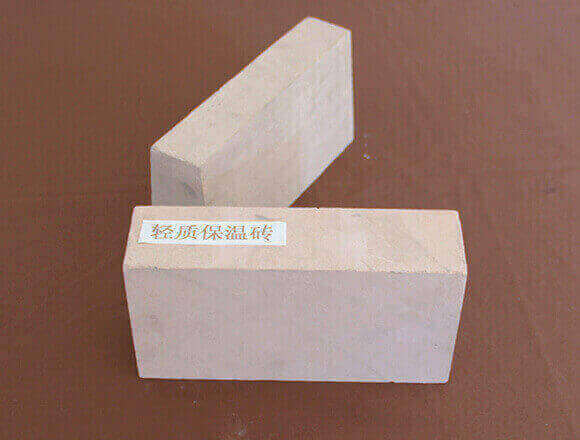

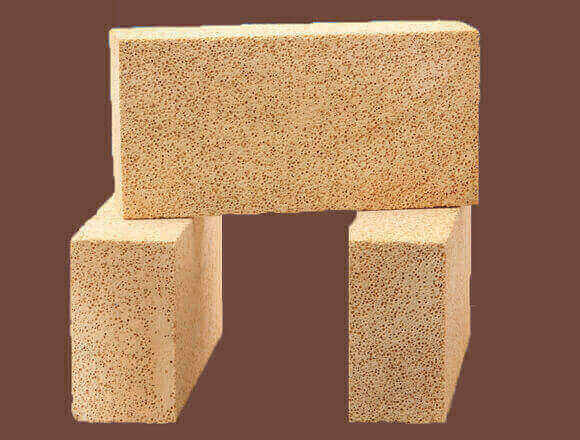

Light weight high alumina brick is also named high-aluminium heat insulation brick, are used in building heat insulating walls or heat preserving walls, which is basically for preserving or insulation heat. Refractory insulation thermal brick contains more than 48% alumina oxide.

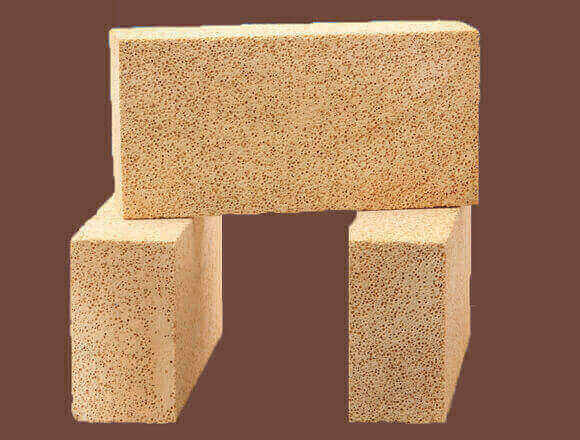

Light weight high alumina brick is also named high-aluminium heat insulation brick, are used in building heat insulating walls or heat preserving walls, which is basically for preserving or insulation heat. Refractory insulation thermal brick contains more than 48% alumina oxide. This kind of thermal brick for sale does not directly exposed to high temperature inside kilns or furnaces, thermal brick only built closely to the kiln wall as insulations. Refractory insulation thermal brick is a good insulation refractory material, which has a high compressive strength, low thermal conductivity and good insulation quality.

Because refractory insulation thermal brick with smaller bulk density whose strength is not as strong as heavy weight fire bricks, when delivering, CH Refractories will package refractory insulation thermal brick with special packages to protect products from damage.

Applications of High Alumina Insulation Brick:

Light Weight High Alumina Brick is used in parts that is not exposed to abrasions and high temperature of melted matters. They should not be applied in environment that has a temperature higher than 1400℃.

As a low price refractory material, the light weight high alumina bricks are applied in:

●Ceramic tunnel kiln

●Roller kiln and shuttle kiln

●Furnace lining and insulation layers

●Other Thermal Equipment & Heat Treatment Lining

●Heating Furnace & Coking Furnace In Iron And Steel Industry

Advantages of CH series High Alumina Insulation Brick:

●High compressive strength

●Widely application with different bulk density

●Free sample,Free construction guidance ,free 3D design

●Good insulation performance,low thermal conductivity

●Customerize mould according to different size requirements for free

|

Brands |

CH-LG-0.6 |

CH-LG-0.8 |

CH-LG-1.0 |

|

BD g/cm3 ≥ |

0.6 |

0.8 |

1 |

|

CCS /Mpa ≥ |

1.96 |

2.94 |

4 |

|

The reheating line changes by no more than 2% of the test temperature /℃≤ |

1350 |

1400 |

1450 |

|

Thermal conductivity average temperature 350±25℃(W/m.k) |

0.25 |

0.32 |

0.45 |

|

0.1MpaRUL/℃ ≥ |

1300 |

1350 |

1380 |

|

Al2O3 /%≥ |

48 |

48 |

48 |

|

Fe2O3 /% |

1.8 |

1.6 |

1.5 |

|

Maximum use temperature /℃ |

1300 |

1350 |

1380 |

The iron runner castable that developed by CH Refractories is low cement Al2O3-SiC-C ramming mass, and self-flowing refractory castable, which divided three levels to meet different sizes of blast furnace iron runner and achieved very good performance.

Lightweight thermal insulating castable is formulated with different types of lightweight aggregates, powders, binders and expansion agents. lightweight castable refractory is a good new type of refractory insulation materials and energy-saving materials.

Silica refractory brick is fused silica refractory,a acid refractory brick which mainly consisting of tridymite, cristobalite, and a small amount of residual quartz and glass phases. The silicon content is 94% or more. True density of the silicon brick is 2.35g/cm3.

If you need our products please write down any questions, we will reply as soon as possible.