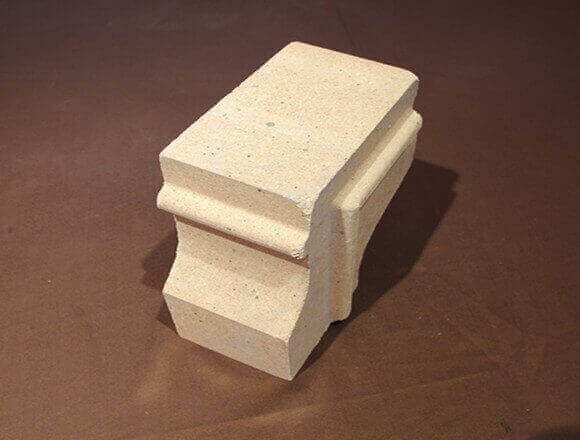

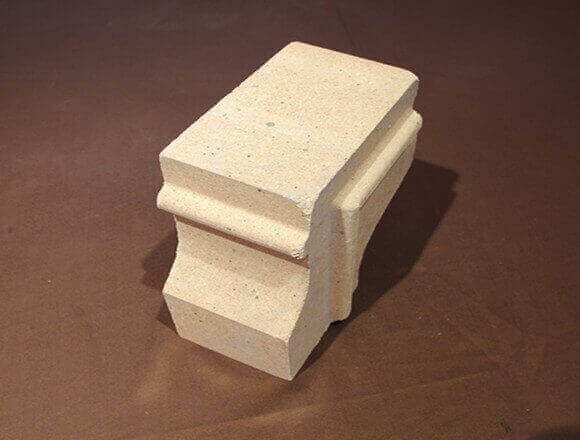

Silica refractory brick is fused silica refractory,a acid refractory brick which mainly consisting of tridymite, cristobalite, and a small amount of residual quartz and glass phases. The silicon content is 94% or more. True density of the silicon brick is 2.35g/cm3.

Silica refractory brick is fused silica refractory,a acid refractory brick which mainly consisting of tridymite, cristobalite, and a small amount of residual quartz and glass phases. The silicon content is 94% or more. True density of the silicon brick is 2.35g/cm3.

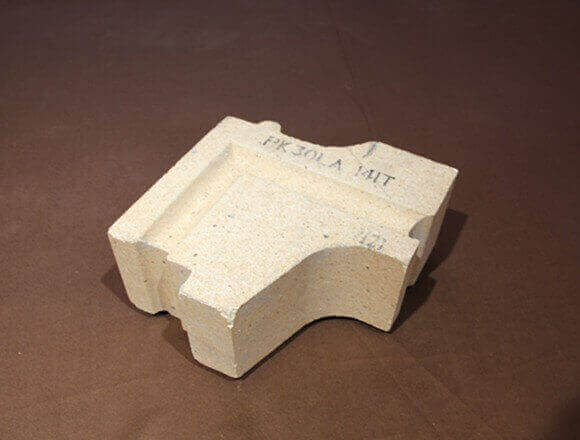

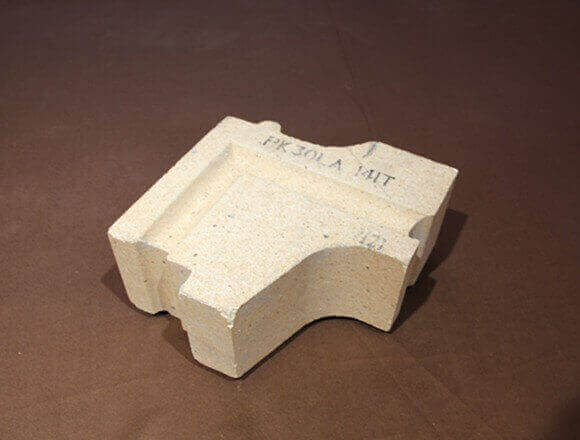

CH Refractories has manufactured and installed SiC bricks for more than 30 years, there are many different kinds molds, when manufacturing, which will save much mold casting time. CH Refractories also can design silica firebricks size for you according to your furnace requirements for free and guide you how to install on site.

Fused silica refractory brick is slowly calcined at 1350℃ to 1430℃ under a reducing atmosphere. When heated to 1450℃, there is about 1.5~2.2% of total volume expansion. This residual expansion will make the joints tight and ensure good air tightness and structural strength of the masonry.

SiO2 has different types of crystals in different temperatures, and the transform between the crystals will cause the change of the bulk. So there is a close relationship between the changes of SiO2 crystals and the produce ,performance and usage of silicon bricks. During the heating, there will be changes of the bulk ,and cristobalite changes most, then quartz phosphorus is the slowest of all and it also has good heat-conductivity. Coke oven should use the silica firebricks with small true density. And the phosphorus quartz is better than others.

Applications of Silica Brick:

●Coke oven

●Hot blast furnace

●Glass melting furnace

Advantages of CH series Silica Brick:

●SiO2 is above 95%

●Acid slag corrosion resistance

●High softening point with temperature

●Free sample,Free construction guidance ,free 3D design

●Customerize mould according to different size requirements for free

|

Items |

common silica brick |

silica brick used for hot blast stove |

|||

|

/ |

CH-GZ-95 |

CH-GZ-94 |

CH-GZ-93 |

Vault brick |

Checker brick |

|

SiO2%≥ |

95 |

94 |

93 |

95 |

95 |

|

Refractoriness/℃ ≥ |

1710 |

1710 |

1690 |

|

|

|

0.2Mpa refractoriness under load℃ ≥ |

1650 |

1620 |

1620 |

|

|

|

Apparent porosity/% ≤ |

22 |

23 |

25 |

22 |

23 |

|

CCS/Mpa ≥ |

29.4 |

24.5 |

19.6 |

35 |

30 |

|

Bulk densityg/cm3 ≥ |

2.37 |

2.38 |

2.39 |

2.35 |

|

|

High temperature Creep(0.2Mpa 1550℃,50h)/%≤ |

|

0.8 |

|||

|

Thermal linear expansion/%(1500℃) ≤ |

|

1.26 |

|||

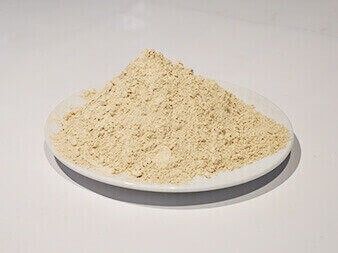

Refractory clay mortar is referred to as soft clay. It isair setting refractory mortar, a refractory clay with plasticity. The constituent minerals of high temperature mortar are mainly kaolinite and hydromica. Generally, refractory mortar mix contains Al2O3 ≥ 22% ~ 30%, SiO 2 ≥ 42% ~73%, and the refractoriness is 1580 ~ 1670 °C.

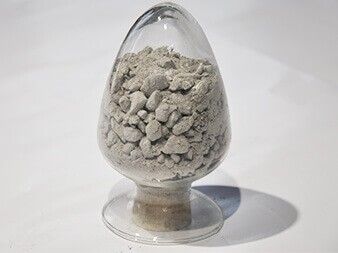

The high-strength wear-resistant self-flowing castables are made of high-quality bauxite clinker, mullite and fused corundum. The pure calcium aluminate cement, corundum micro-powder and silicon micro-powder are used as binders.

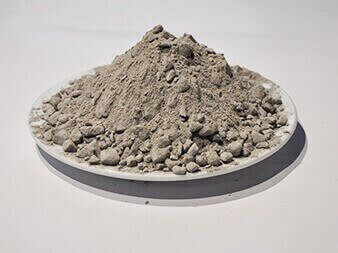

High alumina castable is a kind of refractory castable which uses high alumina raw materials as aggregates and the powder and then be added with binding agent. High aluminum castable refractories has high mechanical strength, good thermal shock resistance, good corrosion resistance.

If you need our products please write down any questions, we will reply as soon as possible.