Siliceous refractory repair material has high load-softening point, low temperature creep rate, high strength, low porosity, strong thermal shock resistance, anti-slag and anti-erosion, and will not damage the repaired structure due to expansionof quartz.

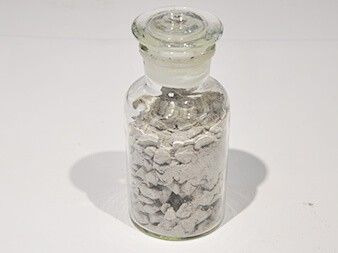

Siliceous refractory repair material has high load-softening point, low temperature creep rate, high strength, low porosity, strong thermal shock resistance, anti-slag and anti-erosion, and will not damage the repaired structure due to expansionof quartz. Siliceous refractory repair material is easy to use and can ensure long-term use of high temperature kiln after repairing and prolonging service life. Siliceous repair material is used for heat repair when the silicon masonry such as glass kiln, coke oven, blast furnace hot blast stove is damaged. Such as: glass kiln big raft, small furnace, breast wall, coke oven carbonization chamber and combustion chamber wall, coking chamber bottom, furnace door and other parts.

|

Refractoriness ℃ ≥ |

1750 |

|

|

0.2MPa refractoriness under load/ ℃ ≥

|

1700 |

|

|

Compressive strength/ MPa≥

|

110℃×24h Drying |

30 |

|

1450℃×3h After burning |

35 |

|

|

Use density kg/m3 |

2300 |

|

|

permanent linear change /%(1450℃×3h ) ≤ |

0.2 |

|

|

Apparent porosity % ≤ |

22 |

|

Corundum mullite high-strength wear-resistant refractory castables have high compressivestrength, good high temperature volume stability and thermal stability, excellent wear resistance and strong corrosion resistance.

High-strength wear-resistant plastic refers to a mixture of high-grade refractory materials such as corundum, mullite or silicon carbide, and a binder and an admixture (anti-shrinkage agent, preservative, antifreeze).

Refractory castable for rotary kiln is suitable for calcination and roasting of cement, limestone,magnesia, ilmenite and non-ferrous metal ore. Castable for rotary kiln has the advantages of strong acid and alkali corrosion resistance and good wear resistance and long service life.

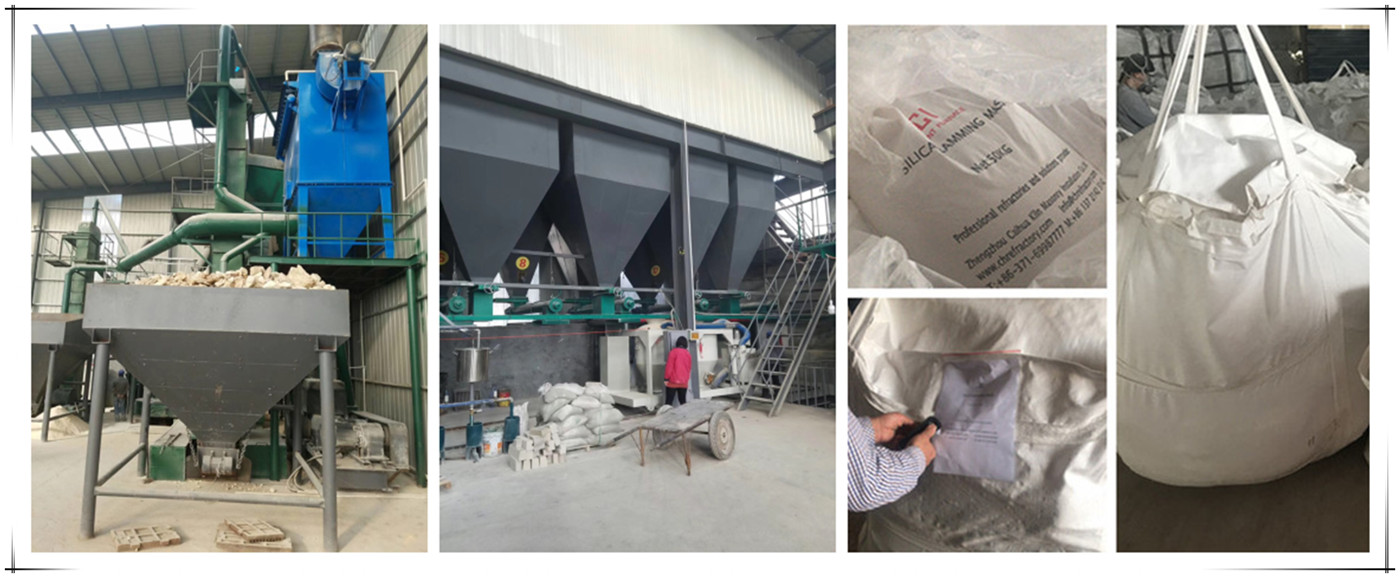

If you need our products please write down any questions, we will reply as soon as possible.